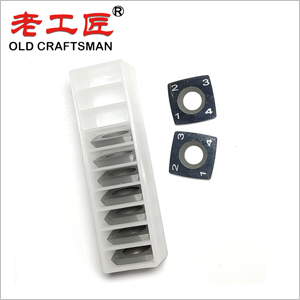

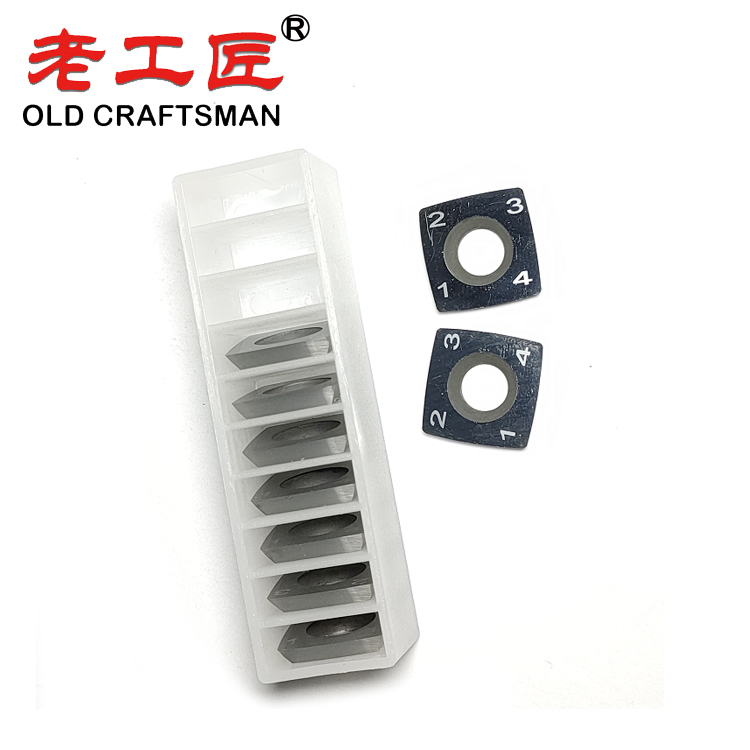

Woodworking Insert

Woodworking Insert

2. Automatic grinding ensures the uniform size

3. Different grades for various application

4. Experienced engineer support the best solution

5. Comprehensive testing ensure 100% qualification

6. Competitive price and fast delivery

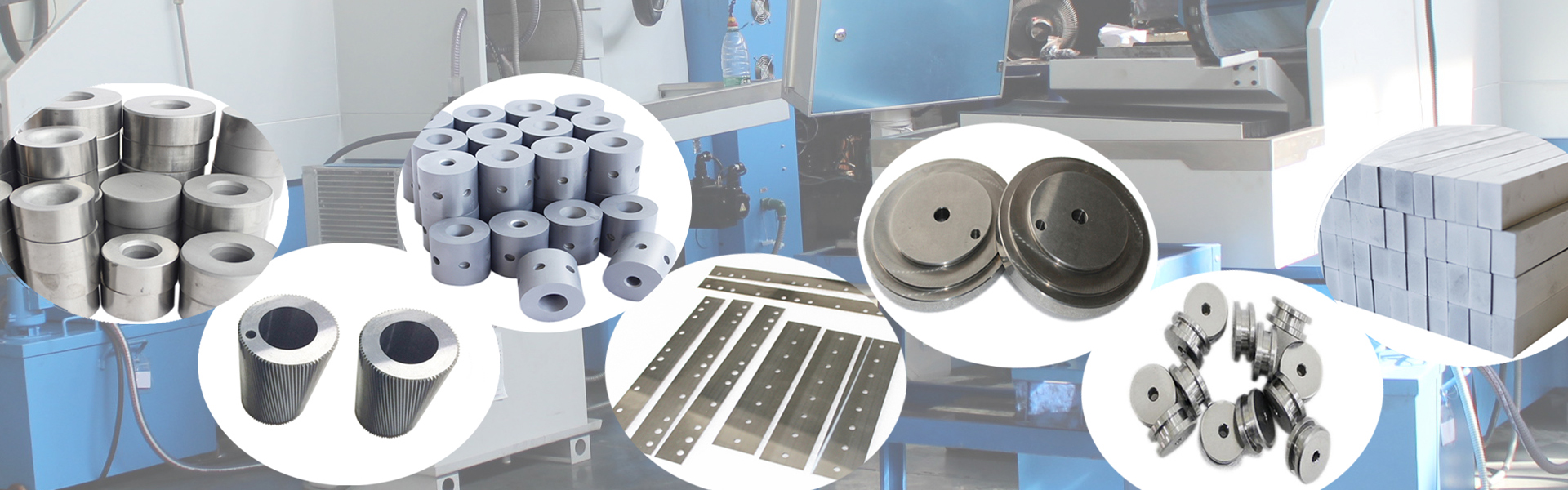

Production Introduction

The woodworking inserts in the picture is not a standard inserts we are talking about. When you see the picture carefully, you will find there was a groove at the sides, which makes the production difficulty much. We cost thousands of USD to design the mold, and the samples were only successful after several round test and design. Also we tested several grades to choose the most proper one. After all the tests succeed, one year passed. But now it belongs to a standard woodworking inserts to our company. We produce and keep in stock according to customer yearly consumption.

The main Grade for woodworking inserts

Carbide grade and properties | |||

Grade | Binder % | Hardness(HRA) | TRS(N/mm2) |

YL10.2 | 10.0 | 91.8 | 2400 |

YG6X | 6.0 | 91.5 | 1800 |

YG12X | 12 | 88.5 | 2300 |

YG15X | 15 | 87.5 | 2600 |

FAQ

Q: Are customized products your company strong points?

A: Yes, we have 2 CNC machining centers for semi-machining, the engineer are in this field for more than 20 years.

Q: What is your MOQ?

A: Depends on the exact products.

Q: can you design the products according to our detailed usage?

A: Yes. Our engineers have rich onsite experience.

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.

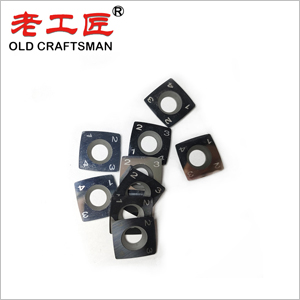

Some Pictures of the Woodworking Inserts