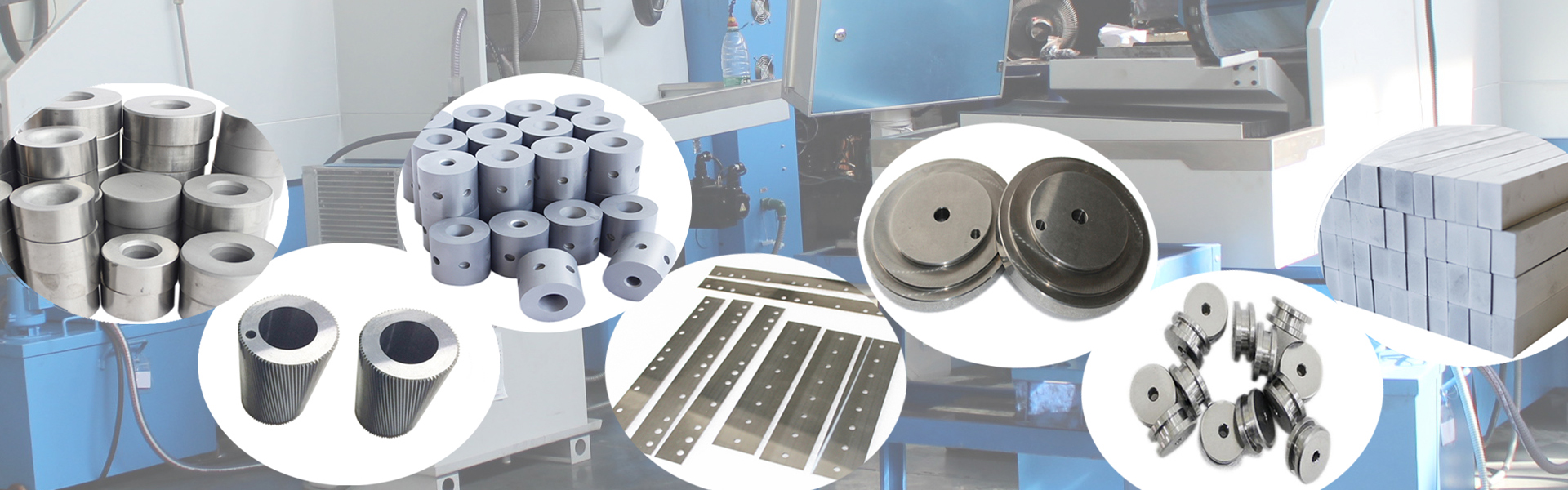

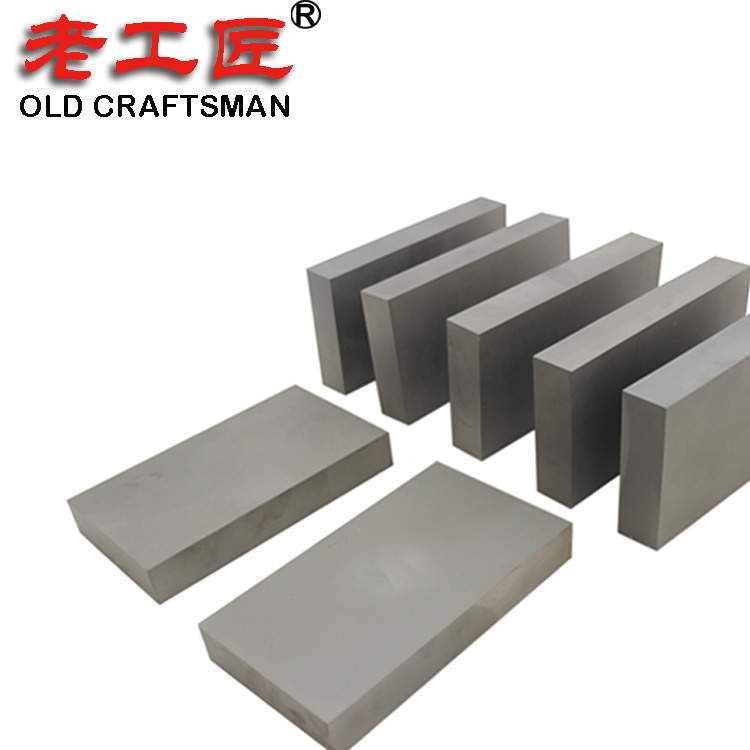

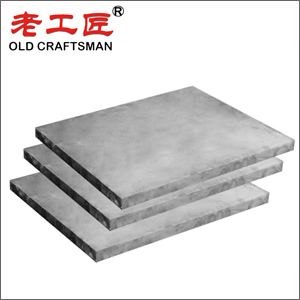

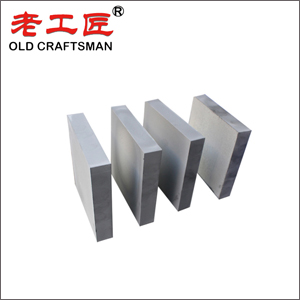

Tungsten carbide Plate

Tungsten carbide Plate

2. HIP sintering

3. 500T presser with side pressure

4. Strict quality control, fast delivery

5. Special deal with to release pressure, to get much better

performance

6. Can develop the grade according to customer different

application

7. fast delivery and good after-sales service

Grade for Tungsten Carbide Plate

GRADE | ISO CODE | COBALT CONTENT | DENSITY | HARDNESS |

(%) | g/cm3 | HRA | ||

K10T | K05-K10 | 4.5-6.0 | 14.95-15.05 | 92.7 |

YG8 | K30 | 8 | 14.8 | 89.5 |

YG6 | K20 | 6 | 14.95 | 90.5 |

YG6X | K10 | 6 | 14.95 | 91.5 |

YL10.2 | K30 | 10 | 14.5 | 91.8 |

YG13X | K30-K40 | 13 | 14.3 | 89.5 |

YG15 | K40 | 15 | 14 | 87.5 |

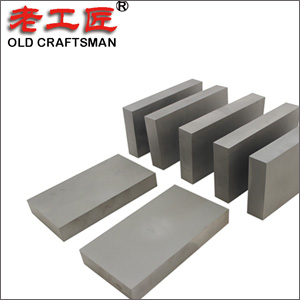

Tungsten Carbide Plate Size Information

L(mm) | W(mm) | T(mm) |

100 | 100 | From 5 to 30 |

105 | 105 | From 5 to 30 |

200 | 200 | From 5 to 30 |

250 | 250 | From 5 to 30 |

300 | 300 | From 5 to 30 |

FAQ

Q: Can you produce special sizes of the tungsten plates?

A: Yes, we can. we have 2 CNC machining centers for semi-machining.

Q: What is your MOQ?

A: 5PCS per size

Q: If we have special requirement on the carbide grade, can you do it?

A: Yes, we can. We have 1L, 10L powder ball mill tank for doing experiments.

Q: We need carbide plates for making mold, can you recommend a grade?

A: Yes. Usually we recommend YG15 for plates used for making mold.

Q: I do not know the grade information, but I have sample, can you test it?

A: Yes, we have full sets of test equipment.

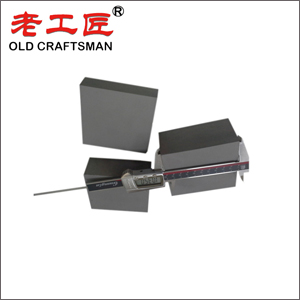

Different Sizes of Carbide Plates

![]()

![]()

![]()

![]()