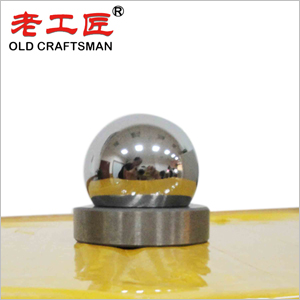

Tungsten Carbide Ball

Tungsten Carbide Ball

2.HIP sintering

3.Accurate blank size, strict tolerance for grinded ball

4.Mirror surface

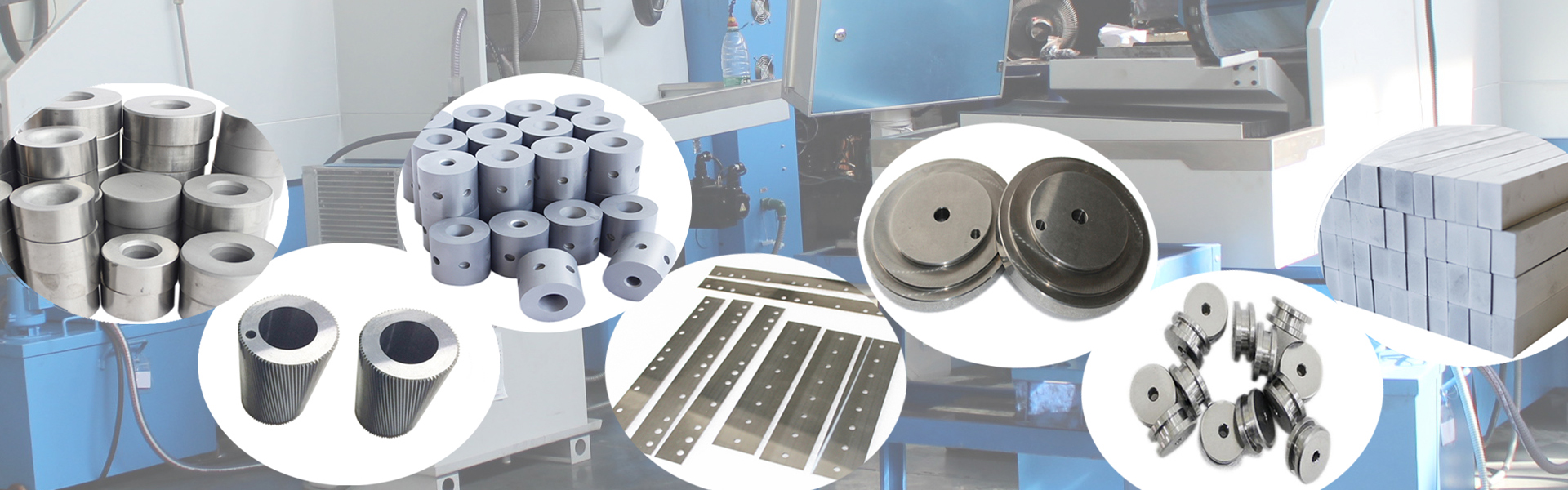

Production Introduction

Carbide ball and seat are mainly used for the sealing of valves of oil pumps in petroleum industry's sand containing wells, viscous oil wells, sea oil wells and high pressure sulfur resistant oil wells, etc. Compatible high precision valve seats can also be made available.

Production Advantages

1. High strength, high wear resistance, high precision, high temperature resistant, corrosion resistant.

2. The surface finish, tolerance class and tolerances of dimensions have respectively reached the standards of the machine industry: G5, G10, G16, G40 and G100 of JB/T 9145-1999.

3. Precision machined cemented carbide balls of other grades and specifications are also available based on customers' demands.

Grade for Tungsten Carbide Ball and Seat

Grade | Density | Hardness | TRS |

YG6X | 14.95 | 91.5 | 1800 |

YG8 | 14.8 | 89.5 | 2200 |

YG11 | 14.4 | 87 | 2500 |

Type and specifications

Dia. | Inch | 3/4 | 7/8 | 15/16 | 1 | 1 1/8 | 1 3/16 |

mm | 19.05 | 22.225 | 23.813 | 25.4 | 28.575 | 30.163 | |

Inch | 1 1/4 | 1 3/8 | 1 1/2 | 1 5/8 | 1 11/16 | 1 3/4 | |

mm | 31.75 | 34.925 | 38.1 | 41.275 | 42.863 | 44.45 | |

Inch | 2 | 1 1/4 | 2 1/2 | ||||

mm | 50 | 50.8 | 57.15 | 60 | 63.5 |

Different Carbide Balls