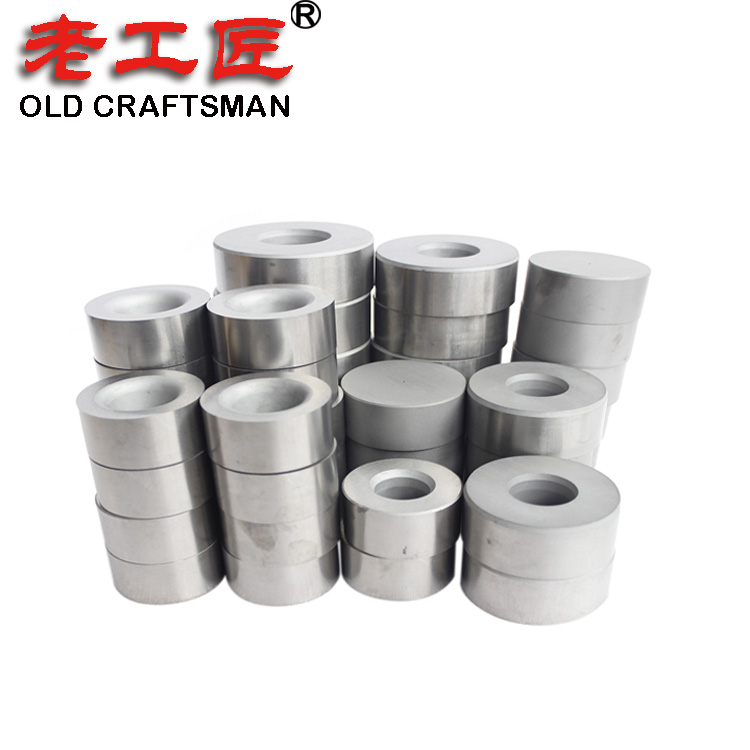

Carbide Drawing Dies for Tube

Carbide Drawing Dies for Tube

material

2. All dawing dies are HIP sintered

3. Our advatage is big diameter carbide drawing dies, free of

mold fee

4. With Semi-machining, no MOQ requirement

5. Accept OEM and ODM, fast delivery and excellent after-

sales service

Production Introduction

Cemented carbide adopts tungsten-cobalt cemented carbide, which is composed of tungsten carbide and cobalt. Tungsten carbide is hard and wear-resistant as the "skeleton" of the alloy, and cobalt is the bonding metal, which increases the toughness of the alloy. As the cobalt content increases, the density, hardness, compressive strength, elastic modulus, thermal conductivity and resistivity of the alloy decrease, while the toughness and flexural strength increase. As the content of tungsten carbide increases, the performance of the alloy is just the opposite of the above-mentioned increase in cobalt content. Cemented carbide has good properties of high wear resistance, corrosion resistance, alkali resistance, anti-emulsion and other lubricating materials. Cemented carbide wire drawing dies are widely used in the drawing production of various metals and alloy wires.

Production Advantages

The tungsten carbide drawing dies use high-quality carbide as the core, which has high hardness, good thermal conductivity and low friction coefficient. Carbide wire drawing die is simple to make, corrosion resistant, strong impact resistance, and low price, which are the outstanding features of this product. It is suitable for drawing ferrous metals, large-size wires, and occasions with poor wire drawing conditions.

Working principle

In metal pressure processing, the metal is forced to pass through the core of the wire drawing die under the action of external force, and the cross-sectional area of the metal is compressed when it is compressed. Finally obtain the required cross-sectional area shape and size wire drawing products, such as steel wire, copper wire. This technical processing method is called the metal wire drawing process.

When drawing fine steel wire, for example, the diameter of the steel wire is less than 0.75mm, fine-grained cemented carbide with cobalt content (by weight) of 3-6% and a hardness of HV1700 can be selected. When drawing and rolling bars, we can consider medium-grain cemented carbide with cobalt content (by weight) of 12-14%. because this cemented carbide can withstand various stresses generated by machining centers. The hardness of this material is only 60-70% of the low-cobalt alloy, but the toughness is better.

Grade Information

Grade | Density(g/cm3) | Hardness(HRA) | TRS(MPa) | Applications recommended |

YG6X | 14.95 | 91.5 | 1800 | For drawing steel and nonferrous wires or bars of less than ¢6.00mm under not so much stress. |

YG6 | 14.95 | 90.5 | 1900 | For drawing steel, nonferrous alloy bars of less than ¢20.00mm under more stress and also for drawing tubes of less than ¢10.00mm. |

YG8 | 14.8 | 89.5 | 2200 | For drawing steel and nonferrous bars and tubes, also for manufacturing mechanical parts, tools and wear parts. |

YG10 | 14.5 | 88.5 | 2400 | |

YG15 | 14 | 87 | 2800 | For drawing steel bars and tubes with a high reduction rate and for manufacturing anvils, drilling and punching and impacting. |

Q: What is your main products?

A: Our main products are carbide dies, carbide strips, carbide shims, carbide wear resistant plates, carbide tiles, customized products and so on.

Q: What is your MOQ?

A: For standard products, there is no MOQ limitation. For non-standard products, MOQ is depends on the exact products.

Q: Do you have OEM&ODM option?

A: Yes, we have. Customized product is our company strong point.

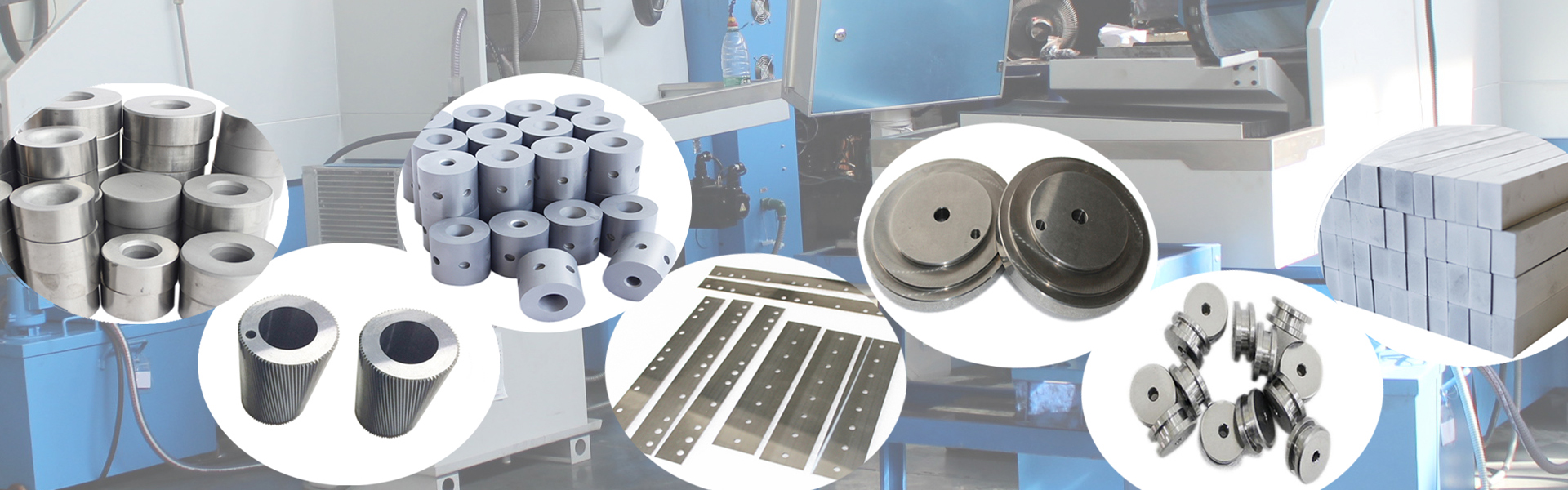

Other Similar Sizes We Are Producing

![]()

![]()

![]()

![]()