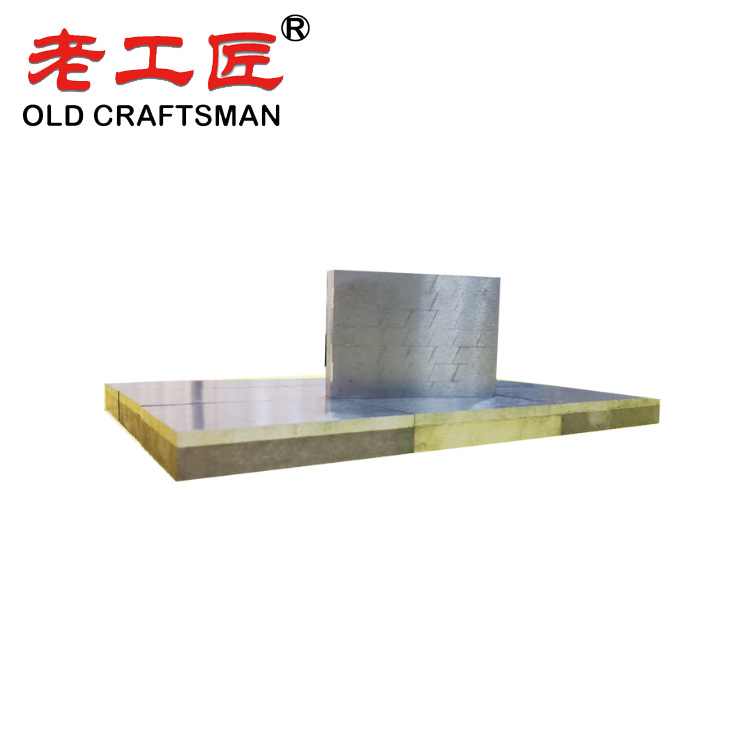

Liner for Refractory Brick Mold

Liner for Refractory Brick Mold

2. Vacuum brazing, high bonding strength

3. Perfect post-processing process, lengthen the using life

4. Excellent after-sale service,quality assured, no worries

Product Introduction:

Liners for press molds is mainly used for refractory bricks mold. Refractory product molds (dies for refractory bricks) refer to models for forming refractory bricks. The shape and geometric dimensions of the mold are designed according to the shape of the product, and its structure consists of a mold frame, a backing plate and a template. The formwork is subjected to the forming pressure exerted by the brick press, which makes a great friction force between the brick and the formwork. Therefore, the surface of the template is easy to wear. Generally, if the wear reaches 0.3-0.4mm, it is not allowed to continue to use. Therefore, the template is required to have good wear resistance. Cemented carbide, etc.

Product development history:

First Generation: Main materials are modified cast iron, A3 steel, mild steel, 45# steel. Improving surface hardness and wear resistance by heat treatment, reach the hardness HRC60-64. Then to make the press mold. The advantage is low cost and fast delivery time, the disadvantage is short using life.

Second Generation: Main materials are tool steel, ultra-high carbon steel. The cost is higher, using life is also longer than normal material. But still can not meet the market requirement on the high effecinence.

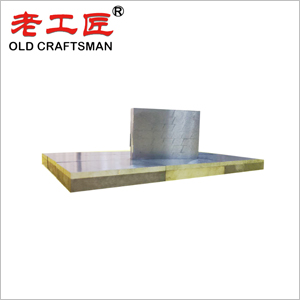

Third Generantion: Tungsten carbide. Brazing the carbide tiles on the steel backing plates. There also several way.

1. Braze the whole carbide plates on the mold, but the carbide is easy to be broken when using them.

2. Braze whole parts with carbide tiles. This way is better than above one, can press about 9400 times, but the using life still can not meet customer requirement. And also have cracks during the usage.

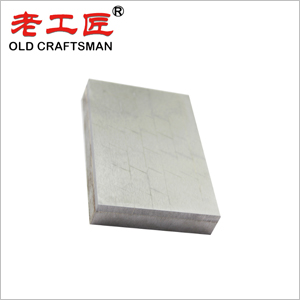

3. Braze carbide tiles with on smaller steel backing plate, drill the thread hole for easy installation. Using this way, the performance increased a lot, can press more than 15, 000 times.

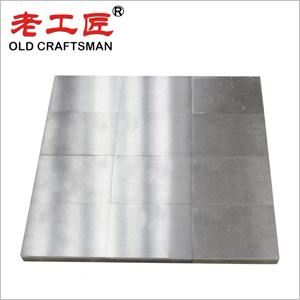

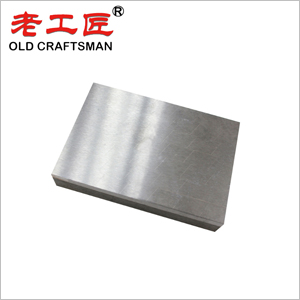

Below are the pictures of the liners for press mold our company produced. This design is popular among our customers and the liner performance are satisfied with customer.