Carbide Brazed Hammer tip and Wear Plates Used for VSI Crusher Rotor

The full name of VSI crusher is a vertical shaft impact crusher, which is used for most crushing applications. The main uses is in quarries and gravel pits to produce products for roads and asphalt, ballast, manufactured sand for concrete and aggregates for use in the construction industry. But VSIs are also used for the recycling of building material, namely concrete and asphalt and the processing of steel slag. Increasingly in a conservation-conscious world, industries must learn to choose the most cost-effective materials to save energy, cost.

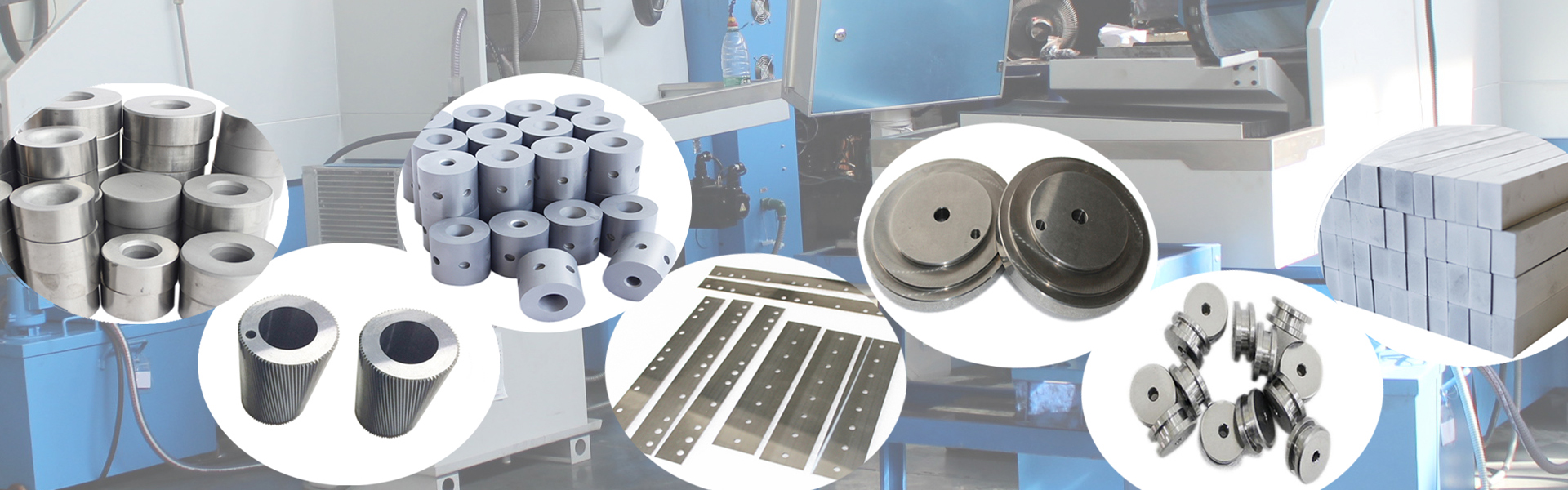

The rotor as a main spare parts for the VSI crusher, its working efficiency effects the whole working line cost. And the wear parts for the rotor is the key parts. The hammer tips and wear plates our company produced as wear parts for the VSI crusher solved this problem easily.The hammer tips and wear plates are produced by carbide welded on steel parts. This design has features of wear resistance and easy install, saving onsite worker time on replacing. The customized carbide grade fully play the high wear and strong impact characteristics.

With VSI crusher, the raw material starts its journey from the feed hopper. It enters the rotor through a central entrance. At this point, the raw material moves through a spinning pump. The wear parts for the VSI crusher rotor play the most important role in this process. and VSI crushers are a crucial part of making industrial sand, so its production cost is a direct and main cost for many products such as abrasives, ceramics, glass, paint, sealants, and more.

Benefits of using carbide welded hammer tips and wear plates for the VIS crusher rotors:

1. Versatile and Efficient: Carbide has high impact, crushes hard and brittle materials with ease.

2. Simple to Install: The steel backing plates with thread hole makes it is easy to put in place and keep up.

3. Energy-efficient and Durable: The abrasion resistance of carbide is much higher than other tranditional materials, longer using life gives you a large volume of output while keeping its energy consumption levels down.This feature may also reduce your maintenance expenses.