Cemented Carbide Classification and Usage

Cemented carbide is usually classified according to alloy composition, and the use description is relatively scattered.

Classification

Cemented carbide: including WC-Co, WC-TaC-Co, WC-TiC-Co, WC-TiC-TaC-Co, WC-Ti-TaC-NbC-Co and other alloys, these alloys are all tungsten carbide Main ingredient.

Titanium carbide-based or titanium carbonitride-based cemented carbide: usually composed of TiC or Ti (C, N) as the basic component and Ni-Mo as a binder. There have been many new developments in this type of cemented carbide in recent years, such as the development of high-performance Ti (C, N)-based cermets by adding multi-element compound carbide solid solutions containing heavy metal elements such as Ta and W.

Chromium carbide-based cemented carbide: a cemented carbide based on Cr3C2 and Ni or Ni-W as a binder. It is usually used as wear-resistant and corrosion-resistant parts. In recent years, it has also been widely used in decorative parts. Such as bracelets and so on.

Steel-bonded cemented carbide: a cemented carbide based on TiC or WC and steel as a binder. It is an alloy that can be machined and heat treated. It is between traditional cemented carbide and alloy steel. A kind of engineering material between.

Coated cemented carbide: usually refers to coating a few microns of TiC, TiN, Ti (C, N), Al2O3, etc. on the tough tungsten carbide-based cemented carbide substrate by chemical vapor deposition or physical coating method Produced from hard compounds.

use

Cemented carbide has a series of excellent properties and has a wide range of uses. The uses are still expanding over time.

Usage

Cutting tools: Cemented carbide can be used as a variety of cutting tools. The amount of cemented carbide used in cutting tools in my country accounts for about one-third of the total cemented carbide output, of which about 78% are used for welding tools and about 22% are used for indexable tools. The cemented carbide for CNC tools only accounts for about 20% of the cemented carbide for indexable tools. In addition, there are cutting tools such as solid cemented carbide drills, solid cemented carbide small circular saw blades, and cemented carbide micro drills.

Geological mining tools: Geological mining tools are also a major use of cemented carbide. Cemented carbide for geology and mining in my country accounts for about 25% of the total cemented carbide production. It is mainly used for drill bits for percussion drilling, drill bits for geological exploration, down-the-hole drills for mining and oil fields, roller cone drills, and picks for coal cutters. , Impact drills for the building materials industry, etc.

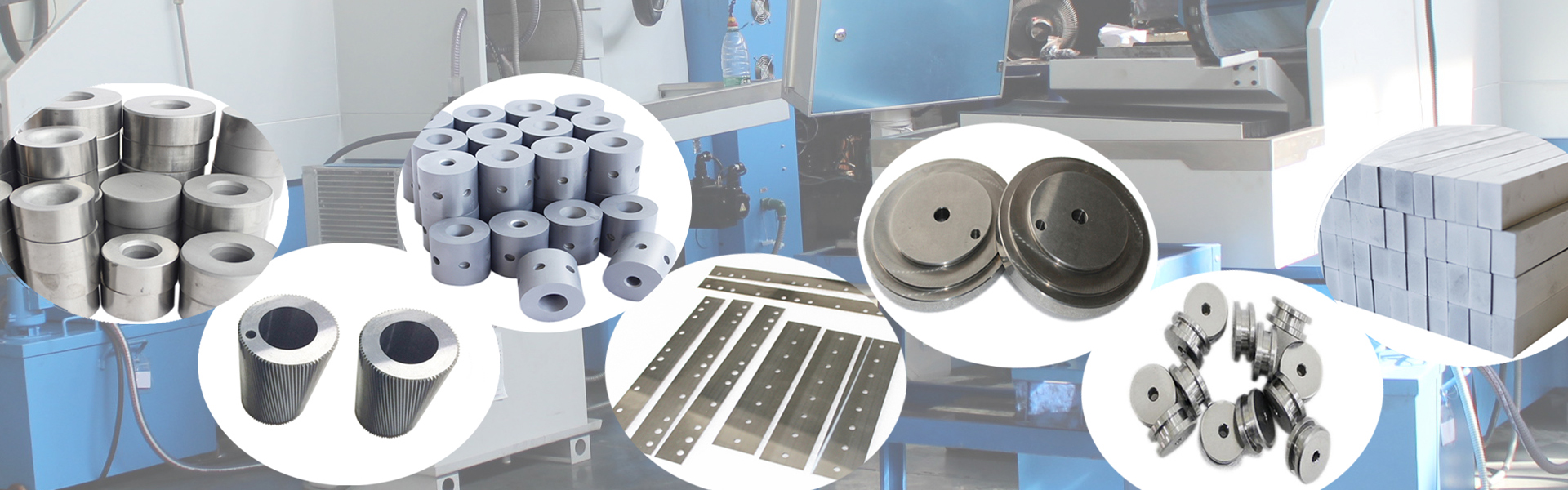

Die: The cemented carbide used as various dies accounts for about 8% of the total cemented carbide production, including wire drawing dies, cold heading dies, cold extrusion dies, hot extrusion dies, hot forging dies, forming dies and drawing dies Tube core rods, such as long core rods, spherical core rods, floating core rods, etc., in the past ten years, the amount of various cemented carbide rolls used for rolling wire rods has increased rapidly. 3% of the total.

Structural parts: There are many products made of cemented carbide as structural parts, such as rotating seal rings, compressor pistons, lathe chucks, grinding machine spindles, bearing journals, etc.

Wear-resistant parts: Wear-resistant parts made of cemented carbide include nozzles, guide rails, plungers, balls, tire cleats, snow plow boards, etc.

Cavity for high pressure and high temperature resistance: The most important use is to produce top hammers and pressure cylinders for synthetic diamond. The cemented carbide for top hammers and pressure cylinders has accounted for 9% of my country's total cemented carbide production.

Other uses: The use of cemented carbide has become more and more extensive, and has been continuously expanded in the civilian field in recent years, such as watch chains, watch cases, zipper pulls for high-end luggage, and cemented carbide trademarks.