How To Choose Hammer Head For Hammer Crusher

The main working part of a hammer crusher is a rotor with a hammer (also known as a hammer head). The rotor is composed of a main shaft, a disc, a pin shaft and a hammer. The motor drives the rotor to rotate at a high speed in the crushing cavity. The hammer head is the main easy to wear part, and the quality of the hammer head directly affects the crushing efficiency of the crusher. During the working period, the hammer head is not only impacted but also impacted by the material. In this way, if it is repeatedly used for a long time, the working surface of the hammer head will be damaged and the surface shape will change. Most of the hammer heads of domestic hammer crushers are made of high manganese steel. The material is fed into the machine from the upper feeding port, and is crushed by the impact, impact, shearing and grinding action of the high-speed moving hammer. In the lower part of the rotor, there is a sieve plate, and the particles smaller than the sieve hole size in the crushed material are discharged through the sieve plate, and the coarse particles larger than the sieve hole size are retained on the sieve plate and continue to be hit and ground by the hammer, and finally pass through the sieve plate Exhaust from the machine.

Hammers are widely used in various crushing industries such as coke, coal, coal gangue, metallurgy, glass, mining ore, cement factory limestone, clinker, brick factory leaf rock, etc.!

According to the material, the hammer head of the crusher can be divided into: high manganese steel hammer head, bimetal hammer head, composite hammer head, large gold tooth hammer head, medium chromium alloy hammer head, cemented carbide hammer head, etc.

The crusher hammer head produced by our company is used vacuum brazing with customized carbide grade, the performance is tens times longer than widely used material.

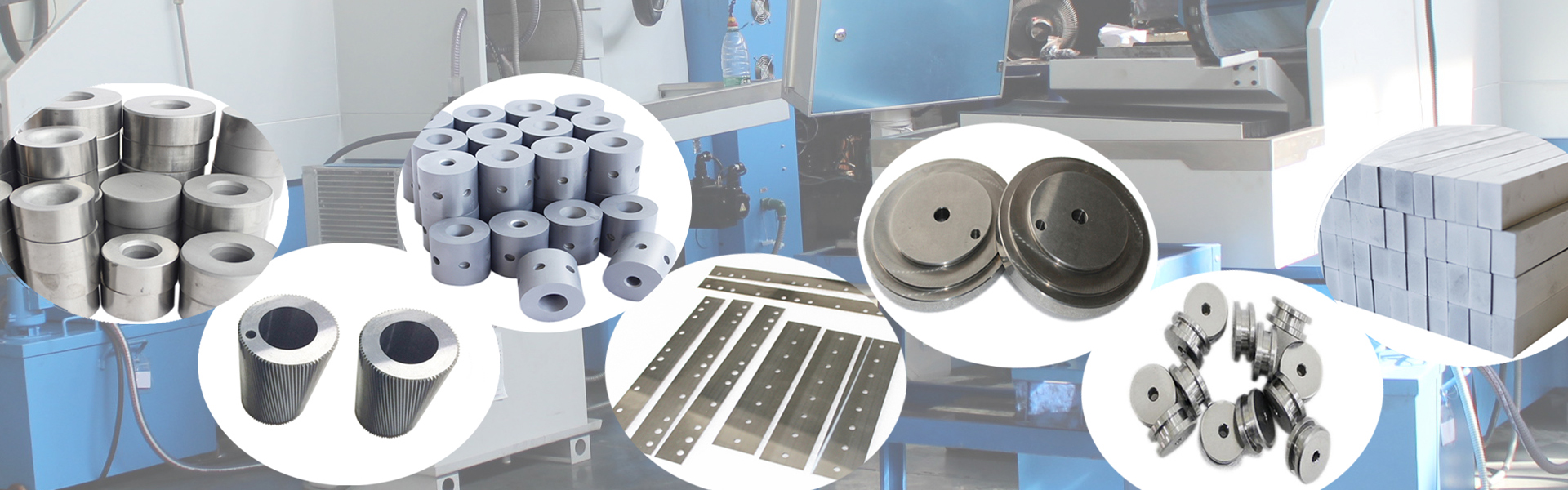

Below is the picture of hammer head that our factory manufactured.